Pageviews

Monday, December 16, 2013

Thursday, December 5, 2013

Tanalising Timber Process

Tanalising Timber Process

1) The Tanalising process involves placing the timber within the treatment cylinder and creating an initial vacuum within the cells of the timber.

2) The cylinder is then flooded under vacuum with the preservative treatment.

3) Hydraulic pressure is then applied forcing the preservative deep into the timber cells.

4) After a pre-determined period of pressure depending on the species of timber being treated and its eventual use, the treatment solution is pumped back into storage and a final vacuum extracts any excess treatment solution from the timber.

5) Low pressure inside the timber draws in surface solution when vented to the atmosphere and the treated timber is left for a specified period for fixation of preservative to occur

1) The Tanalising process involves placing the timber within the treatment cylinder and creating an initial vacuum within the cells of the timber.

2) The cylinder is then flooded under vacuum with the preservative treatment.

3) Hydraulic pressure is then applied forcing the preservative deep into the timber cells.

4) After a pre-determined period of pressure depending on the species of timber being treated and its eventual use, the treatment solution is pumped back into storage and a final vacuum extracts any excess treatment solution from the timber.

5) Low pressure inside the timber draws in surface solution when vented to the atmosphere and the treated timber is left for a specified period for fixation of preservative to occur

Thursday, November 28, 2013

Wood Joints

Wood Joints

This is a Mortise and Tenon joint and it is a traditional joint and is popular due to its strength. A mortise is simply a hole in the piece wood and the tenon piece slots inside. There are many different forms of mortice and tenons and also uses – but they are mostly used in tables and doors. The reasons why people use mortise and tenon is because it is very simple concept however is extremely effective and quick to manufacture.

This style of butt joint is the simplest of all methods of joining two pieces wood together. However the strength of the joint relies entirely on the glue and any additional fixings such as screws. This type of joint is often used on bed frames as it causes the different parts to be lined up so the product fits together correctly.

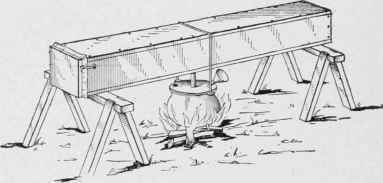

Steam Bending Notes

Steam bending is a technique used on woods in order for them to change shape. During the process strips of wood/timber are steam heated using a steam box. A steam box is a long sealed container which is where all of the steam bending process takes place. Then the heat and mositure makes the wood more flexible which allows the timbers shape to be changed. However during the process the shape has to be held by a mould so that is doesn't have chance to change back to its original shape.

Steam bending is relatively cheap, effective and quick however there is a disadvantage that the wood can only bend to a certain degree. Which can be a pain depending on the purpose that you want to use the wood for.

Steam bending is relatively cheap, effective and quick however there is a disadvantage that the wood can only bend to a certain degree. Which can be a pain depending on the purpose that you want to use the wood for.

|

| This is a image showing a steam box |

|

| This is showing a steam bending jig |

Monday, November 11, 2013

Manufactured Boards Notes

Hardboard: is a high-density wood fibreboard and a standard material used in

furniture making and in the carpentry industry. The production process

results in one very smooth side and a rougher side due to the way that it is manufactured. It is a extremely dense fibreboard. It is manufactured and sold at a thickness of 3mm.

Plywood: is a manufactured board that has properties including increased stability, high impact resistance, dimensional stability, high strength to weight ratio, chemical resistance. Plywood is generally known as an assemblage of wood veneers bonded together to produce a flat sheet. Which is machined to a thickness of 6mm and is sold at that thickness.

Blockboard:is made up of a core of softwood strips that are extremely thin. These strips may be up to about 25mm wide however they are normally . The strips are placed edge to edge and sandwiched between veneers of hardwood. The sandwich is then glued under high pressure. In order to compress it and make sure that no water enters any gaps that are left. It is sold at a thickness of 18mm and this is the thickness that it is machined to this thickness initally aswell.

Chipboard:is made by gluing together wood particles with an adhesive, under heat and pressure makes chipboard. This creates a rigid board with a relatively smooth surface. Chipboard is available in a number of densities: -normal, medium and high-density. Is sold at a thickness of 18mm.

Medium-Density Fibreboard (MDF)- is a reconstituted wood panel product. It is a dry-processed fibreboard manufactured from wood fibres, as opposed to veneers or particles, and is denser than plywood and particleboard. MDF has an even density throughout and is smooth on both sides.

Plywood: is a manufactured board that has properties including increased stability, high impact resistance, dimensional stability, high strength to weight ratio, chemical resistance. Plywood is generally known as an assemblage of wood veneers bonded together to produce a flat sheet. Which is machined to a thickness of 6mm and is sold at that thickness.

Blockboard:is made up of a core of softwood strips that are extremely thin. These strips may be up to about 25mm wide however they are normally . The strips are placed edge to edge and sandwiched between veneers of hardwood. The sandwich is then glued under high pressure. In order to compress it and make sure that no water enters any gaps that are left. It is sold at a thickness of 18mm and this is the thickness that it is machined to this thickness initally aswell.

Chipboard:is made by gluing together wood particles with an adhesive, under heat and pressure makes chipboard. This creates a rigid board with a relatively smooth surface. Chipboard is available in a number of densities: -normal, medium and high-density. Is sold at a thickness of 18mm.

Medium-Density Fibreboard (MDF)- is a reconstituted wood panel product. It is a dry-processed fibreboard manufactured from wood fibres, as opposed to veneers or particles, and is denser than plywood and particleboard. MDF has an even density throughout and is smooth on both sides.

Thursday, November 7, 2013

Timber & Wood drying methods Notes

Air-Drying Timber -This is a method of drying timber by exposing it to natural conditions. As such

there is no control over drying rate as this will be determined by the weather conditions , which will vary considerably throughout the year. The average time for timber to dry using this method is 5 weeks.

Kiln-Drying Timber -This is a method of using heat via steam that is involved through a tube to reduce the moisture content of the timber by using heat to heat it so that the water evaporates from the wood, some companys have also tryed reducing atsmospheric pressure in order to speed up this process.

Wednesday, November 6, 2013

Thursday, October 3, 2013

Uses of Thermoplastics and their properties

Uses of Plastics and there

properties

ABS - Acrlonite butadiene styrene is used

for the manufacture of Lego because it has to be strong, durable, impact

resistant and also cheap to manufacture due to the fact that it is used by

children.

CA - Cellulose Acetate- is mainly used for packaging, handles and toys as it is used because it is tough and strong.

Nylon – Polyamide- It’s main properties are toughness, that its hard wearing, and has a good resistance to chemicals and machines. It is used for Bearings, gear wheels, casings for power tools, hinges for small cupboards, curtain rail fittings and clothing.

PMMA – Acrylic – Its main properties are that its Stiff, hard , durable, good electrical insulator, therefore it is used for Signs, covers of storage boxes, aircraft canopies and windows

PP- Polypropylene- It’s main properties are that it is Light, hard, tough, and has a good resistance to chemicals. Therefore it is used for Medical equipment, containers and hinges.

PS- Polystyrene- It’s main properties are that it is light, stiff brittle and also got a good strength-weight ratio. It is used for packaging and also some disposable cups.

LDPE- Tough, good resistance to chemicals, flexible and is used for Packaging, especially bottles and also toys.

HDPE- Polyethylene- It’s main properties

are that its hard stiff and easily can be made sterile so its used for plastic bottles

and containers.

PVC- Polyvinylchloride- It’s main properties are that its durable, cheap and is a good fire resistant. Its main uses are for water pipes, tubing and hoses.

PET- Polyethylene Terepheluate- It’s main properties are that its fully recyclable and sustainable and they also use it because of its high strength – weight ratio and its mainly used for drinks bottles. It’s made via blow moulding as it’s quick, accurate and cost effective.

PC-Polycarbonate- Its main properties are that its strong waterproof and durable and is used for honeycomb sheets.

HIPS- High Impact Polystyrene – Its main

properties are that its durable, rugged and also is wear & water resistant

and is mainly used for packaging.

Monday, September 30, 2013

Thursday, September 26, 2013

Polymer Notes and Homework

Polymers - Plastics

Polymers are created by the joining of monomers (polymerisation).

2 Types Thermosetting and thermoplastic

Thermosetting - are only molded once, non-recyclable and there are links between polymers to stop them moving its to complex.

Thermoplastics - can be reshaped if they are reheated many times and are more common.

General Properties of Polymers:

Good conductrors and insulators

Strong for the weight of the product

Good resistance to chemicals

Low melting point

Lightweight and durable

Ways of improving properties of polymers:

Fillers- are added to give it extra bulk and make it cheaper.

Flame Retardants - when the fire is present they slow down the spread of the fire

Anti-static agent - reduces static charge build up.

Stabalisers - reduces the effects of UV Light onto plastics

Thermo-Polymers:

ABS - Acrlonite butadine styreine

CA - Cellulose Acetate

Nylon - Polymide

PMMA - Acrylic

PP- Polypropellene

PS- Polystyrene

PE- Polyethelene

PVC- Polyvinalchloride

PET- Polyethelene Terepheluate

PC-Polycarbonate

Thermosetting Plastics:

Expoxy Resins- Adhesives.

Melamine Formaldehyde- Tables.

Polyester Resins- Castings used in GRP.

Urea Formaldehyde - Electrical Fittings and adhesives.

Homework:

Injection molding process:Plastic in the form of granules is melted until soft enough to be injected under enough pressure to fill a mould.

The result is that the shape is exactly copied. Once the plastic moulding has cooled enough to harden the mould opens releasing the part.

The main reasons for using a mould are:

Quicker

Safer

Faster

More Accurate

You can produce more efficiently

Polymers are created by the joining of monomers (polymerisation).

2 Types Thermosetting and thermoplastic

Thermosetting - are only molded once, non-recyclable and there are links between polymers to stop them moving its to complex.

Thermoplastics - can be reshaped if they are reheated many times and are more common.

General Properties of Polymers:

Good conductrors and insulators

Strong for the weight of the product

Good resistance to chemicals

Low melting point

Lightweight and durable

Ways of improving properties of polymers:

Fillers- are added to give it extra bulk and make it cheaper.

Flame Retardants - when the fire is present they slow down the spread of the fire

Anti-static agent - reduces static charge build up.

Stabalisers - reduces the effects of UV Light onto plastics

Thermo-Polymers:

ABS - Acrlonite butadine styreine

CA - Cellulose Acetate

Nylon - Polymide

PMMA - Acrylic

PP- Polypropellene

PS- Polystyrene

PE- Polyethelene

PVC- Polyvinalchloride

PET- Polyethelene Terepheluate

PC-Polycarbonate

Thermosetting Plastics:

Expoxy Resins- Adhesives.

Melamine Formaldehyde- Tables.

Polyester Resins- Castings used in GRP.

Urea Formaldehyde - Electrical Fittings and adhesives.

Homework:

Injection molding process:Plastic in the form of granules is melted until soft enough to be injected under enough pressure to fill a mould.

The result is that the shape is exactly copied. Once the plastic moulding has cooled enough to harden the mould opens releasing the part.

The main reasons for using a mould are:

Quicker

Safer

Faster

More Accurate

You can produce more efficiently

Thursday, September 5, 2013

Assignment One - I Should never have purchased !

The BukCase

This is the BukCase which is a product that my parents purchased for me last year.

They purchased the Bukcase because on the internet the product looked good and was aesthetically pleasing due to the book look given by the side panels. Also the fact that all the edges were smooth and nicely presented, however it did not fit the purpose! When we went to fit the iPad into the case it kept slipping out. This was due to a serious design flaw that the corner pieces were not strong enough to hold the iPad in place for more than a few seconds at a time. This was clearly a big issue and this left me with a product that looked good but did not perform the function that I was after. This was due to a poor design that needed to be adjusted to make the product function correctly and make it able to perform the functions that I required from the product. Another feature of the product that made me want the product initially was the fact that it claimed to be made out of plywood and that the product was also hand crafted which gave me a reason to trust that the product was going to be good quality due to the fact that the designer (Waqar) had to make the product himself giving me the assurance that he checks the quality of the product before he gets them packaged up and sent out to their customers.

This is the BukCase which is a product that my parents purchased for me last year.

They purchased the Bukcase because on the internet the product looked good and was aesthetically pleasing due to the book look given by the side panels. Also the fact that all the edges were smooth and nicely presented, however it did not fit the purpose! When we went to fit the iPad into the case it kept slipping out. This was due to a serious design flaw that the corner pieces were not strong enough to hold the iPad in place for more than a few seconds at a time. This was clearly a big issue and this left me with a product that looked good but did not perform the function that I was after. This was due to a poor design that needed to be adjusted to make the product function correctly and make it able to perform the functions that I required from the product. Another feature of the product that made me want the product initially was the fact that it claimed to be made out of plywood and that the product was also hand crafted which gave me a reason to trust that the product was going to be good quality due to the fact that the designer (Waqar) had to make the product himself giving me the assurance that he checks the quality of the product before he gets them packaged up and sent out to their customers.

Subscribe to:

Posts (Atom)